Since 1990, Contatore Engineering has been manufacturing and supplying heavy machinery, attachments, parts and accessories to make landscaping, demolition, construction, quarrying and mining work more efficient. We specialise in knowledge about all types of buckets and accessories for excavators. This month, we want to share some of that expertise with you.

Since 1990, Contatore Engineering has been manufacturing and supplying heavy machinery, attachments, parts and accessories to make landscaping, demolition, construction, quarrying and mining work more efficient. We specialise in knowledge about all types of buckets and accessories for excavators. This month, we want to share some of that expertise with you.

Excavator buckets are an essential piece of equipment for earthmoving projects. They serve many functions to accelerate and facilitate the process of digging, ripping, cutting, sifting through, and moving topsoil, rock or dense matter. Most buckets are made from quality high tensile steel plates, which make them incredibly durable and strong. The distinctive styles of buckets that exist add to the versatility of the role of an excavator on a worksite.

Below are some of the types of buckets Contatore Engineering has in its catalogue:

Skeleton/Rake Bucket

These types of buckets are made from high tensile steel round bars, with various gaps between them for the purpose of sifting. These buckets have thick reinforcing panels on the back side of the bucket so it can move and sift through all sort of heavy materials. A rake bucket is often used for sifting larger chunks of matter like rocks, concrete or bricks out from finer materials such as topsoil or sand. It is a useful tool for separating and cleaning as it allows top soil and natural resources at a site to remain intact.

Batter Bucket

Some buckets exist solely for the function of moving large amounts of soft materials like dirt, sand, and other debris. The batter bucket, otherwise known as a mud bucket, gummy bucket or clean-up bucket – do not have any teeth on the front edge, making this style specialised for cleaning up sites and back-filling holes. This bucket is an essential for any landscaping work site and to create batters/side walls on dams and draining ditches.

Tilting Bucket

Another important piece of equipment for moving and tidying up work sites is the tilting bucket. A tilting excavator bucket assists onsite for levelling or forming slopes, as well as back-filling holes when necessary. The structure of a tilting bucket has no teeth which allows more space for materials to be moved and smoothed out. With innovative hydraulic actuator driven controls, tilting buckets make for more efficient and precise general groundwork and landscaping.

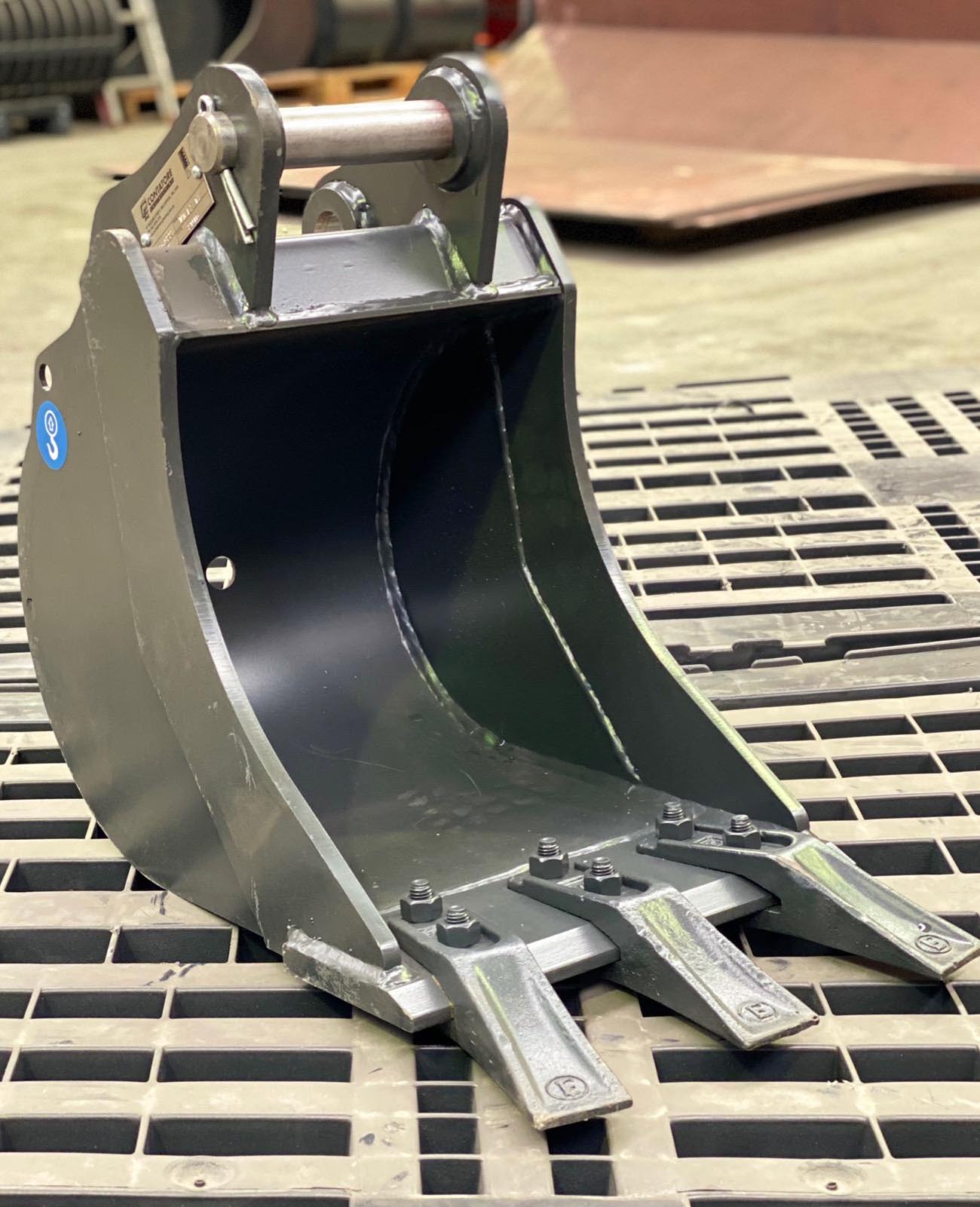

Rock Bucket

Rock buckets are the heavy hitters of the excavator bucket family. These buckets are made to withstand the full strain of any job. They are made with high strength, wear and durability in mind, with strong ripping teeth to loosen earth while digging and are structurally reinforced to withstand high impacts. This bucket is a mining industry favourite and is especially popular now as we continue to experience strong demand and prosperity in our mining sector.

Since manufacturing our first bucket in 1992, Contatore Engineering has a long history of providing an extensive range of the highest quality steel buckets and accessories. Fun Fact; the first bucket we ever made was a Rock Bucket to suit a CAT 992 Loader!

A partnership with Cangini Buckets beginning in 2019 has only increased our catalogue; specifically our range of mini excavator buckets and foundation of knowledge.

Who knows your business needs better than you? Contatore Engineering takes care to manufacture all types of excavator buckets and loaders to our clients’ specifications. You can also rely on us for repair and maintenance services to make sure your equipment will always work as hard as you do. If any of the buckets mentioned above sound like the next piece of equipment for you and your business, contact our team today. We look forward to discussing your needs and finding the best fit for your project!