ROCK BREAKERS – SOCOMEC

Contatore Engineering is the sole and exclusive distributor for Socomec Australia wide and in New Zealand. We offer this innovative and hard-hitting range of Rock Breakers for both sale and hire.

Socomec offers a light to medium range, and a medium to heavy range. They provide breakers to suit 0.7 tonne excavator machines up to 100 tonne excavator machines. Recent unchallenged technological advancements made by Socomec now result in all breakers of up to 47 tonne capacity being equipped with the revolutionary Monoblock design without tie rods.

The DMS range of breakers is manufactured as a sole piece made from a fully forged rod, sporting the huge advantage of having eliminated the tie rods; the main issue often encountered with traditional breakers, therefore making them much more secure and reliable. Two vulcanized polyurethane shells isolate the monoblock from the metal case, reducing noise level and vibrations. Moreover, in case of break down they are much simpler and economical to service than traditional counterparts.

Socomec is confident in the design and quality of their rock breakers that they also offer a 10 year warranty on the monoblock. The bushes avoid contact with the monoblock and moving parts, so there is virtually no wear.

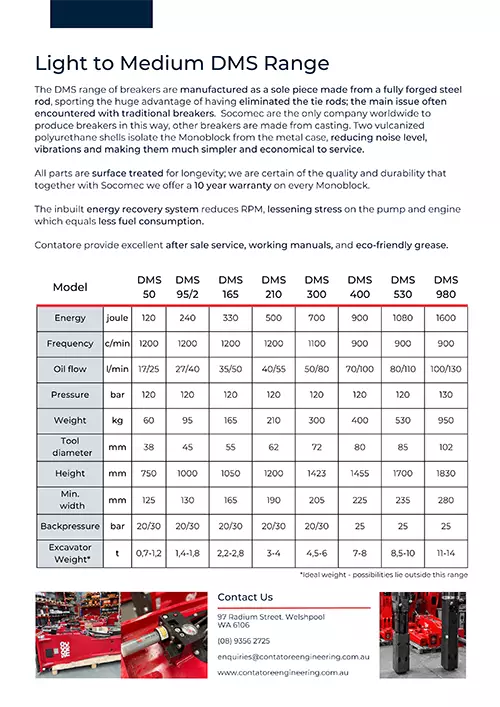

SOCOMEC DMS LIGHT TO MEDIUM RANGE

The light to medium range of Socomec Rock Breakers are ideal attachments for a wide range of machines/excavators. The versatility of the range makes them highly useful in areas where operating space is at a premium, and where access with larger machines may be restricted.

The smallest breaker available weighs 60kg, ranging up to 950kg. These attachments can provide energy for strokes from 120 joules to 1600 joules, and may be fitted on excavators ranging from 0.7 to 15.5 tonne.

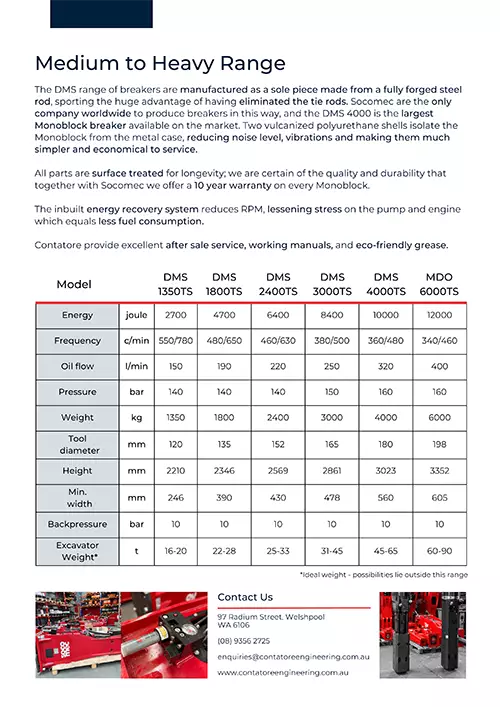

SOCOMEC DMS/ MDO MEDIUM TO HEAVY RANGE

The medium to heavy range of Socomec Rock Breakers are extremely durable and powerful units; our team will guide you to ensure you are matched up with a breaker that meets your specific requirements.

The smallest breaker available weighs 1350kg, ranging up to 6000kg. These attachments can provide energy for strokes from 2700 joules to 12000 joules, and may be fitted on excavators ranging from 15 to 100 tonne.

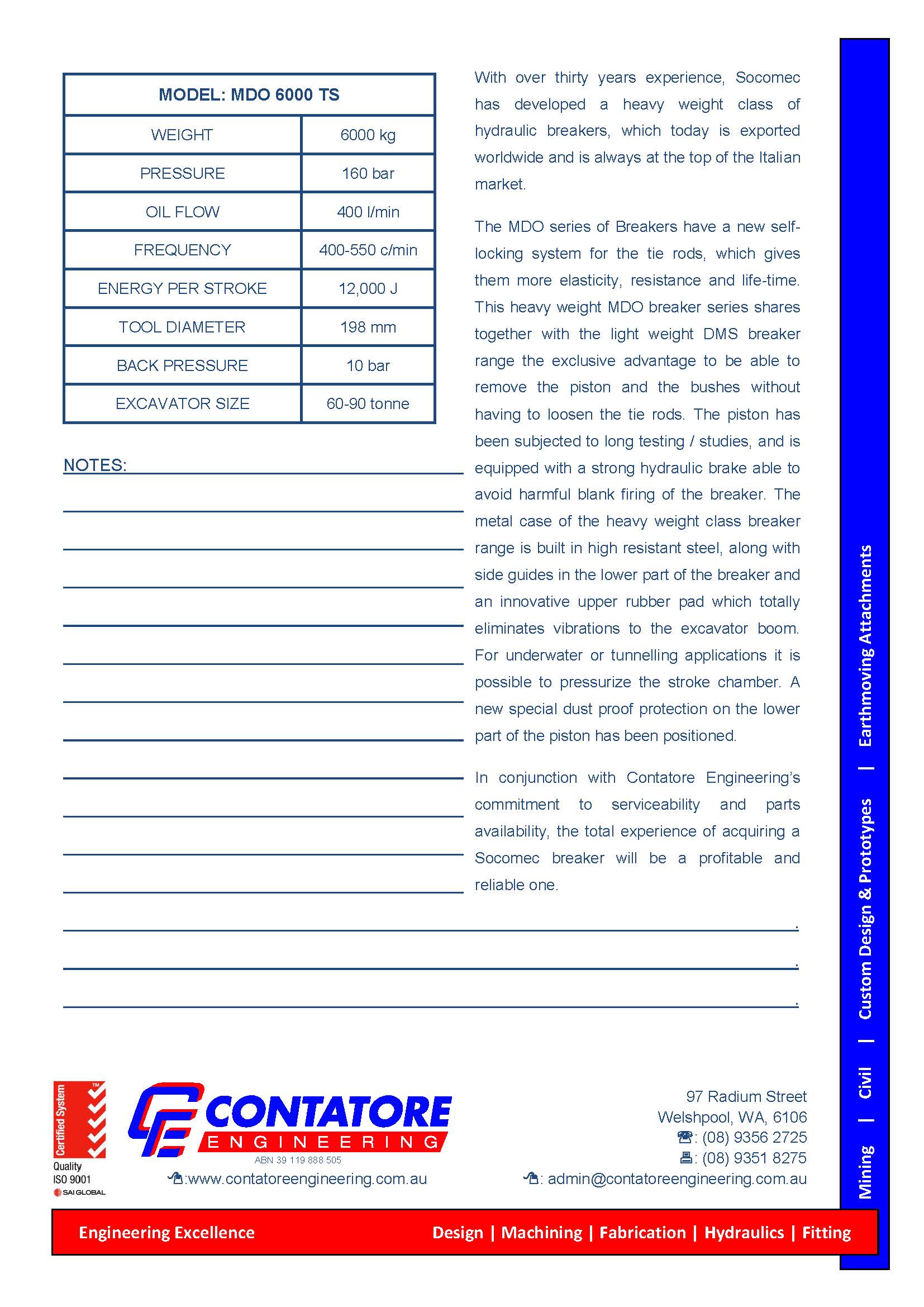

The two heaviest breakers, MDO 4100TS and MDO 6000TS, are excluded from the DMS range, and are equipped with a patented self-locking tightening system for the tie rods, that gives them more elasticity, resistance and longer working life. As with the DMS range, the MDO range has the exclusive system of removal of the piston and internal sleeves without loosening the tie rods.

ROCK-BREAKER / HAMMER

Contatore Engineering offer a range of Rock breakers for sale or hire.

For underwater or tunneling applications it is possible to pressurize the stroke chamber. New special dust proof protection on the lower part of the piston has been incorporated.

In conjunction with Contatore Engineering’s commitment to serviceability and parts availability, the total experience of acquiring a Socomec breaker will be a cost-efficient and profitable one.

Backed by almost 50 years of research and development at Socomec, there is simply no other choice if you require a rock breaker that is reliable, durable, and will do the job properly. We supply parts and services so that you may maintain your breaker. Socomec continues to demonstrate constant innovation in the field and applies patented technical solutions; they are unrivalled in their reliability, productivity and performances.

VIBRATING RIPPERS 20 TONNE – 100 TONNE

We offer a range of vibrating rippers that are efficient in the demolition of medium hardness materials. The function of the vibrating ripper is controlled from within the excavator’s cabin, and they are suitable for 20 tonne to 100 tonne machines. The rippers feature a modern design with quality robust construction that includes low noise technology. The simple and compact design minimizes the likelihood of maintenance operations, while the only part of wear, the tip of the tooth, is easily replaceable.

Vibrating rippers are perfect for the demolition of materials that are too hard for a traditional bucket and too soft for efficient rock breakers, such as limestone, bauxite and coffee rock.

SCREENING BUCKETS

Screening Buckets are ideal to clean stony ground, beaches and to separate and select materials resulting from demolition or excavation. These materials can then be reused, reducing the cost of both disposal and acquisition.

VIBRATING PLATES

Produce a large working force that allows effective compaction in deep soil, excavations and steep slopes.

SELECTOR GRABS

Contatore Engineering can supply a range of Socomec Selector Grabs to suit excavator /machine operating weights from 1.5 tonne to 33 tonne.

The Selector Grabs are extremely versatile, and are ideal for the recycling field and for the selection/sorting of materials from demolition rubble.

HYDRAULIC BRAKE

All Socomec breakers have a hydraulic braking system, which helps to eliminate blank strokes.

AUTOLUBE SYSTEM

MDO series has an automatic greasing unit fitted to rock breakers with no other connections required.

SOUNDPROOFING

The innovative soundproofing system reduces noise by approximately 50%. This is achieved by using special guide and coating plates that completely isolate the breaker from its frame.

UNDER WATER OPERATION

It is possible to use the breaker underwater and for underground mining.

CYLINDER GUIDE BUSHES

In the Socomec construction, the piston is not directly in contact with the cylinder but it slides in a series of guide bushings. When resealing is necessary, it is possible to remove the piston and bushings without loosening the breaker tie-rods. This cost-saving design is exclusive to Socomec.

SEALING SYSTEM

Three seal rings between the cylinder lining bushes and the piston and further seals between the lining bushes and the cylinder offer excellent protection from oil leaks. Low friction type seals are used which do not overheat and have a long service life. A large wiper seal on the tool keeps dust out of the lower chamber and helps to keep grease inside the breaker. It also helps to reduce noise levels.

STROKE VARIATION

Socomec breakers deliver the highest productivity in any material. This is achieved by variation of the blow frequency and impact energy. The breaker reacts to the resistance of the material to be broken and is designed to work always at maximum efficiency.

ENERGY RECOVERY

Thanks to the piston recoil energy, some of the oil already used is directed back to the pressure chamber and is spent on the next stroke. This system increases the breaker power and productivity without drawing further energy from the excavator.

DOUBLE DAMPING SYSTEM

The perfect hydraulic balance of the moving parts avoids all possible breaker recoils. Shock absorbers are built into the breaker frame above and below the breaker to avoid transmitting micro vibrations to the excavator arm.

PISTON DESIGN

Socomec has designed a long stepped section piston that delivers a very powerful impact to the tool and assures the owner of the highest productivity.